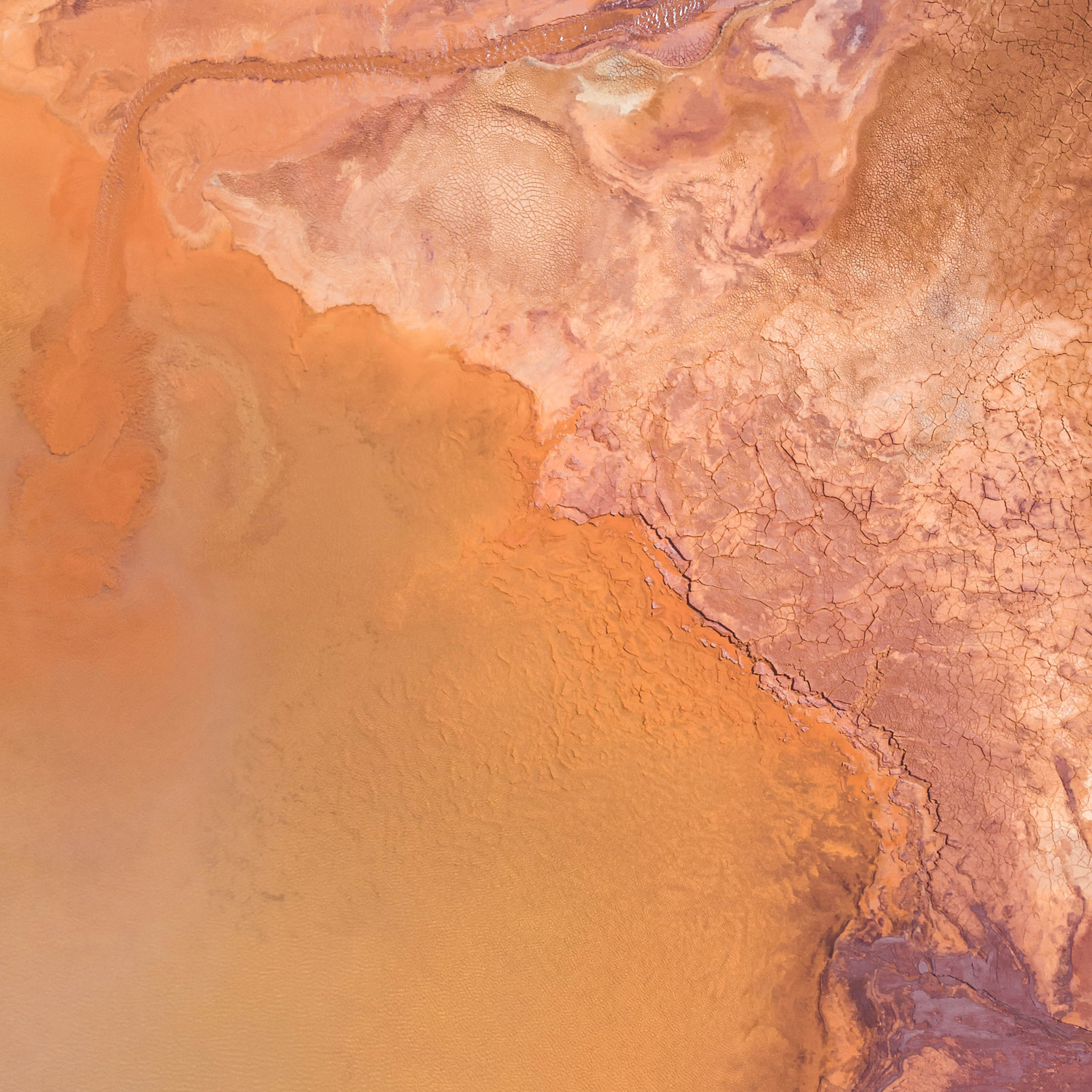

Formulated Rock

Formulated Rock

Formulated by Nu-Rock,

inspired by nature.

Formulated by

Nu-Rock,

inspired by nature.

Non-cementitious masonry manufacturing

The complete absence of cement in

Nu-Rock products is a win for the environment and for the Building, Construction and Mining industries.

Formally commissioned university studies have verified Nu-Rock’s patented process reacts with the minerals and heavy metals contained within industrial waste such as all Coal Ash, all Steel Mill, all Non-Ferrous metal, Alumina red mud, Hard Rock Mine Tailings wastes and other mainstream waste materials. This natural exothermic reaction immediately converts waste material into an impenetrable form known as “Formulated Rock.”

Emissions free manufacturing

Nu-Rock‘s “Formulated Rock” technology involves an emissions free manufacturing process. A vast improvement on the centuries-old, energy-hungry processes involving the quarrying, transporting and kiln burning of limestone at 1500°C. Plus, the quarrying and transporting of precious and finite natural resources such as sand and aggregates. Or energy hungry Clay based product manufacturing that involves a 7-day warming and drying process at 500°C followed by a 3-day firing process at 1050°C.