Green Technology

As a world leading and award-winning Green Technology, Nu-Rock’s unique technology is a fully integrated and game changing process that delivers unique sustainable solutions on multiple fronts.

Large scale industrial and mining waste-site recycling and remediation.

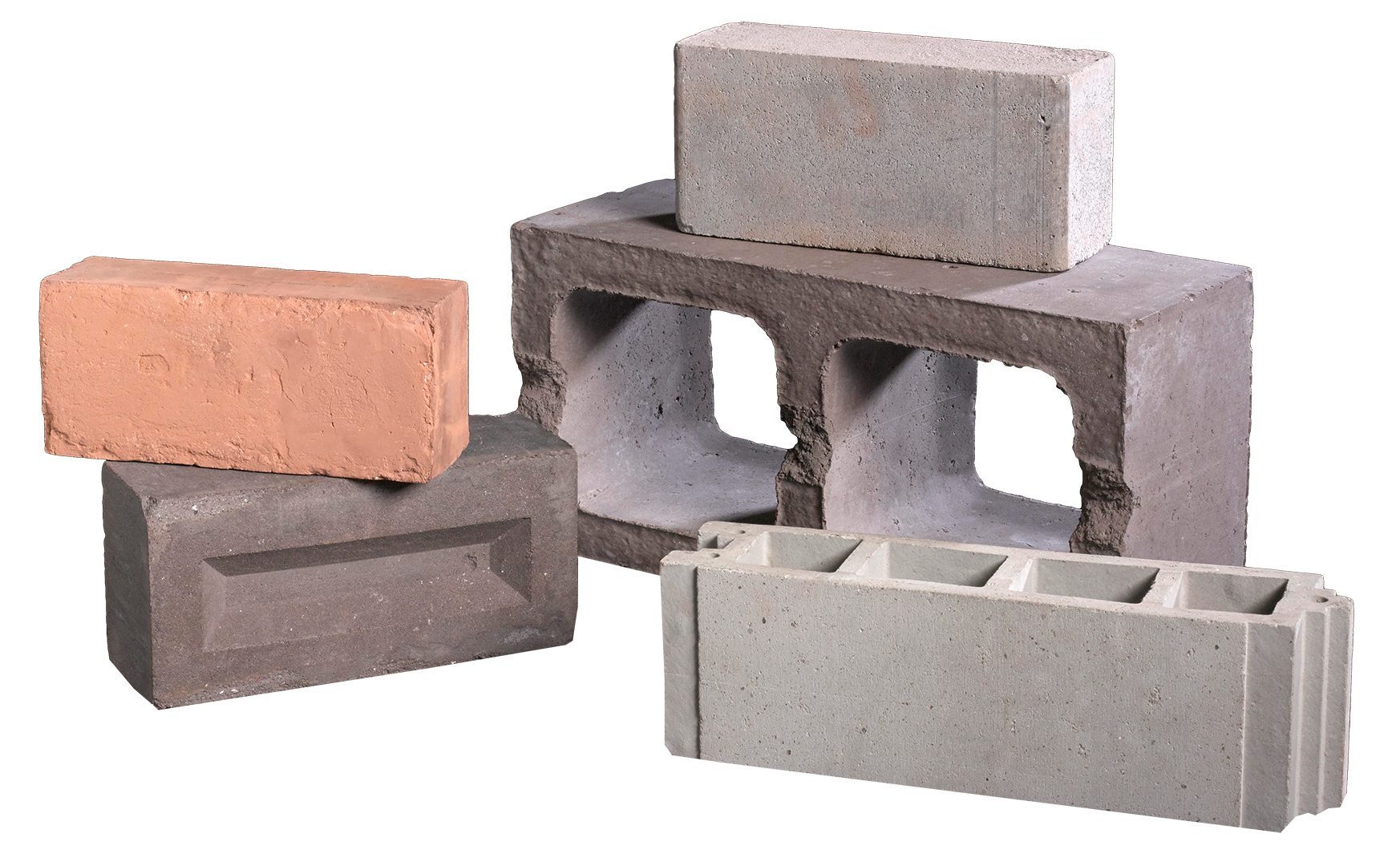

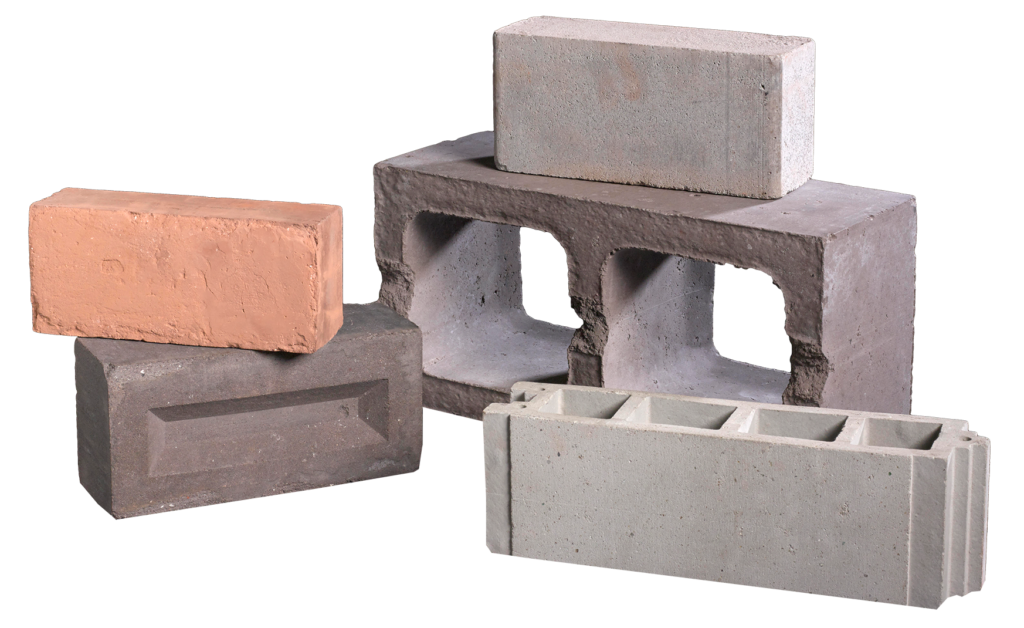

Emissions free manufacturing of 100% sustainable, circular economy building products.

Carbon Utilisation that absorbs and abates high volumes of CO2.

Nu-Rock Building Products Australia is licensed to utilise Nu-Rock Technology for the manufacture of Building Products in Australian and Pacific region.

World leading manufacturing

World leading manufacturing

In addition to protecting the natural environment by cleaning up decades-old waste sites and by manufacturing revolutionary new green building products, sand and aggregates, Nu-Rock’s world leading non-cementitious manufacturing processes absorb and mineralise CO2 at a rate of 5 to 20% per Tonne of material processed, depending on the product and the application.

Our world leading manufacturing processes absorb and mineralise

238% more

CO2 than concrete per tonne of material*

* Depending on the product and the application.

Australia’s largest by 2026

On the back of planned operational scaling, Nu-Rock Licensees are on track to become Australia’s largest carbon mineralisation companies by 2026 and will have and removed in excess of xx million tonnes of CO2 from the atmosphere.

Reclaim and repurpose

Over the coming decade Nu-Rock Licensees will reclaim and repurpose over five million tonnes of coal ash from Australian Power Station ash dams, plus over five million tonnes of wastes stockpiled at Australian Steel works, Non-Ferrous Metal Smelters, Alumina Smelters, and Mines.

Game changing

Nu-Rock Licensees will recycle over one million tonnes of household plastic waste, glass and rubber tyres into ‘game changing’ building products and aggregates.